Details

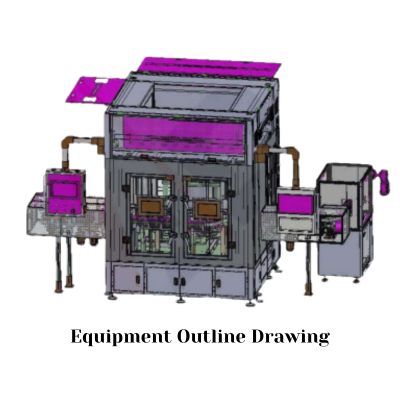

MODEL NAME: 150KV X-RAY INSPECTION SYSTEM WITH TDI DETECTOR

150 kV X-ray Inspection System with TDI Detector: Advanced Precision for Industrial Imaging

The 150 kV X-ray Inspection System complete with a TDI Detector is designed to be a high-end industrial imaging solution, boasting highly detailed and accurate images over a very wide range of applications, whether quality control or non-destructive testing, or meticulous examination of complex components. Voltage range, running within a wide range from very low to very high, supplemented with advanced detector technology and robust construction, allows this system to become the optimum choice for the industries involved in trustworthy and effective inspection capability.

Technical Specifications

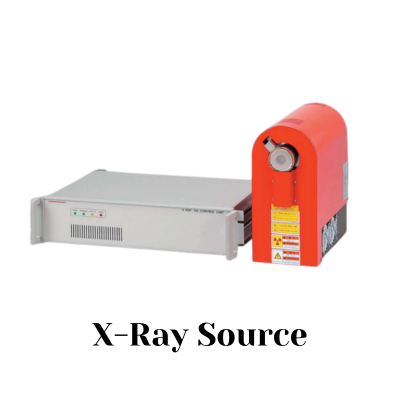

• Voltage Range: 0 to 150 kV

• Output Power: Up to 75 W

• Target Material: Tungsten

• Window Material: Beryllium

• Input Voltage: 100-240 V, 50/60 Hz

• Power Consumption: Less than 220 W

Key Features

1. High Voltage Range for Versatility

Operating on variable voltage from 0 to 150 kV, the system allows for flexibility in a wide range of inspection tasks. The very wide voltage range thus allows for fine tuning of the X-ray output to the density and composition of the material under test, enabling quality imaging across a broad range of applications in electronics, aerospace, and automotive components.2. High-Power Output for Quality Imaging

The 150 kV X-ray Inspection System will provide an output power of up to 75 W for the required energies to allow passage through dense materials and yield highly resolved images with internal structures. The fact that such high power is involved also entails not only continuous operation but very reliable operation, too, over a long period, even under demanding industrial use.3. Advanced TDI Detector for Superior Image Resolution

TDI Detector-Advanced sensor technology for high-resolution real-time images that will raise the image quality of the system. Increased sensitivity and contrast by this advanced detector mean that any little defects like cracks, voids, or inclusions are visualized, which may not be possible with conventional X-ray systems.4. Durable Tungsten Target

The material of the tungsten target should be such that it provides strength for a long period with high thermal conductivity so that the system may work for extended periods without any compromising on its performance. Due to its high atomic number, the tungsten has also been very suitable to produce X-rays with excellent power of penetration; hence these kinds of inspection tasks raise no challenge at all.5. Beryllium Window for Enhanced Efficiency

The beryllium window of the X-ray tube advances the system performance by offering minimum absorption to the X-rays. As this material itself is highly transparent to X-rays, it allows most of the generated radiation to be employed in the process of imaging. This yields sharper images and delivers high performance of the system.

Multiple-Industry Applications

-Electronics Inspection: To detect faulty components on a PCB or soldering defects.

-Aerospace & Automotive: Non-destructive test application in engine parts, turbine blades, and other critical components.

-Medical Devices: Structural integrity tests of implantable devices or other complex medical instrumentation.

-Manufacturing: To check for structural soundness and reliability for quality control of product assemblies.

Why Choose the 150 kV X-ray Inspection System w/ TDI Detector?

The 150 kV X-ray Inspection System incorporates precision, efficiency, and advanced detector technology to achieve the highest level in industrial inspection. This adds to its improved imaging capability, coupled with an added TDI detector, to avail the highest resolution and clarity necessary for the detection of minute defects in high-value or critical components. The robust construction and reliable performance make it an ideal tool for industries needing non-invasive solutions for inspections, quality control, and product verification.

The 150 kV X-ray Inspection System with TDI Detector will be able to help you in the optimization of your inspection process, keeping pace with the highest standards of accuracy and reliability that an industrial process requires.

If you need more detailed information, please do not hesitate to contact us with your quote request.